SAWS Compost Program Facts

-

SAWS launched its first initial pilot Composting Program in 1987 on the grounds of the Leon Creek Water Recycling Center.

-

The composting facilities at Leon Creek WRC were expanded and improved in 1992, and capacity was reached in 1996.

- Expansion of the composting facilities in 1997 will enable SAWS to compost up to 90% of the biosolids produced at its Water Recycling Centers.

- SAWS produces about 25,000 dry tons of biosolids each year, or about 208,000 cubic yards. In the past, landfill disposal costs for these biosolids were over $1.3 million dollars per year. Beneficial use of biosolids eliminates landfill disposal costs.

- In addition to diverting up to 208,000 cubic yards of biosolids from landfills each year, the SAWS Composting Program also beneficially uses up to 150,000 cubic yards of wood chips that would have otherwise been destined for landfills.

- SAWS Compost meets Class A criteria, making it the highest quality of compost possible. It has low trace metal concentrations and few pathogens.

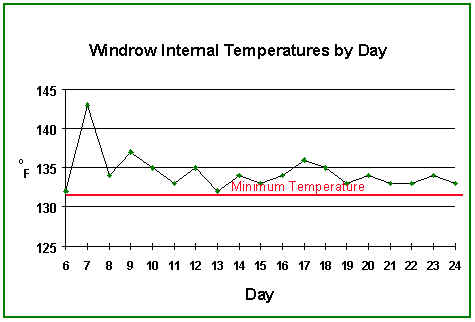

Regulations mandate that temperatures inside compost windrows be maintained above 131°F for at least 15 days. This ensures that disease-causing organisms are destroyed.